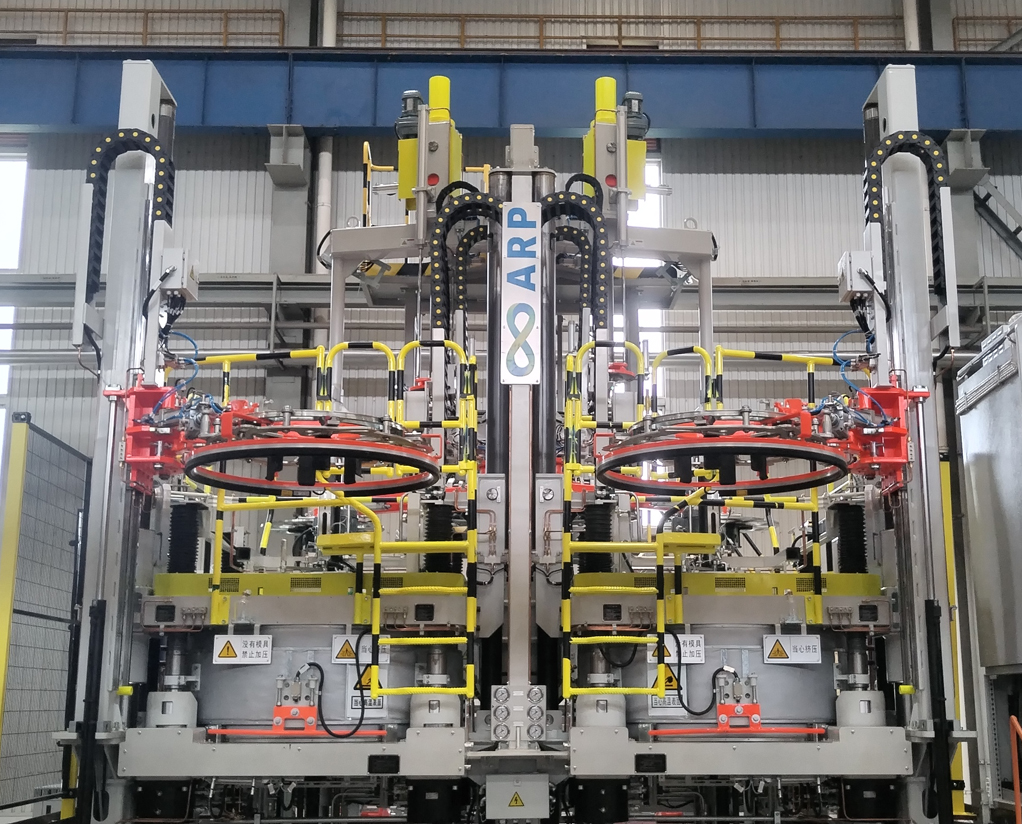

PCR Hydraulic Curing Press

Features: Stable, reliable, efficient, and easy to maintain

In the field of tire manufacturing, ARP curing press have become the ideal choice for many domestic and foreign manufacturers due to their advanced technology, reliable quality, and excellent performance, helping tire manufacturing.

The new generation of semi steel curing press has multiple ARP patented technologies in key technical fields, modular design, and can provide customized services according to customer needs. At the same time, we also have a professional and caring after-sales service team on standby at any time, which can provide customers with one-stop services such as equipment installation and commissioning, operation training, regular maintenance, and fault repair, ensuring that customers have no worries during use and are fully committed to tire production work.

● ARP has independent intellectual property rights and can customize designs according to customer needs.

● Symmetrically arrange multiple pull rods to apply clamping force, ensuring stability and reliability.

● The pull rod is divided into upper and lower parts, with FEA analysis of the main load-bearing components and millions of force tests. The hydraulic system is safe, reliable, and energy-saving.

● The guidance system (not subject to locking force) is separated from the pressurization system to ensure long-term stability and reliability of equipment accuracy.

● The guide column is equipped with multiple safety pin holes, and the mold opening height can be selected according to the tire size to reduce cycle time and improve equipment efficiency.

● Both left and right molds can be vulcanized together or independently for customers to choose from.

● The equipment can be installed with or without a pit.

● Easy to operate and maintain.

● Rich security configurations are available for selection to meet the needs of customers in different countries.