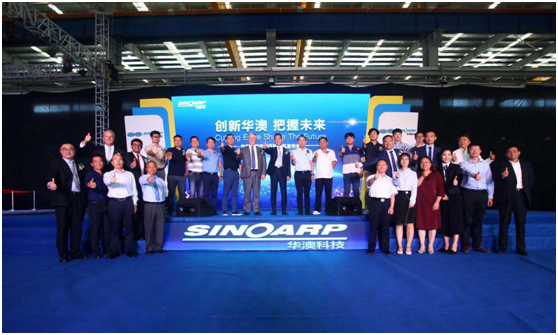

The Fourth Generation Of Hydraulic Curing Press In ARP Was Released, With “Simplified And Economical” Performance. On September 20, the fourth generation of hydraulic curing press of ARP TECHNOLOGIES (SUZHOU) CO., LTD. was honored to be launched in Yancheng coastal factory.

More than 40 businessmen, equipment technicians and media representatives from Michelin Group, Hantai Tire, Kunshan Jianda, Yanchang Petroleum Rubber and other tire customers witnessed unveiling ceremony of new product.

Yao Mingxiao, deputy general manager of ARP Technology, said in his speech at new product release conference that fourth generation of hydraulic curing press in ARP had gone through five years and spent more than 10 million yuan on research and development.

Dominique Cordaillat, customer representative and Michelin Group’s vice president of global procurement, delivered a speech. He said that he was very satisfied with the cooperation at that time when he discovered ARP more than 10 years ago, and business relationship has been maintained till now. Better movement requires better tires and better technology and equipment. I am very satisfied with innovative consciousness and high-quality products of ARP. I hope I can sell them in large quantities and achieve long-term success.

Chen Qiang, chairman of ARP Science and Technology, Zhang Zhengluo, chief engineer, and four customer representatives jointly started the button, unveiling mysterious “veil” of fourth generation hydraulic curing press.

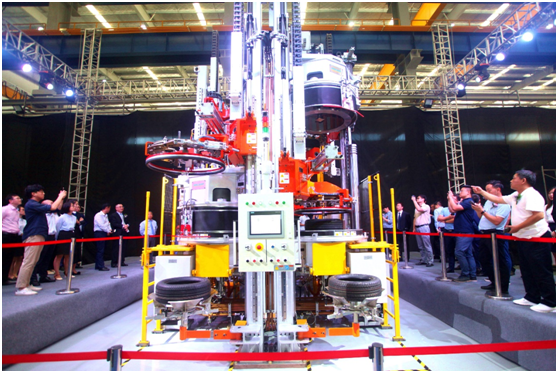

Zhang Zhengluo, chief engineer of ARP Science and Technology, gave a detailed introduction to product’s performance and characteristics. The four-generation machines not only maintain the advantages of original models, but also incorporate the ideas from tire enterprises, adapting to the needs of era of industrial 4.0 and new demands of tire enterprises. The precision, reliability and stability of curing press that tire enterprises pay special attention to have been greatly improved and breakthrough progress has been made. It can be summed up in the words “simplification and economy”.

Refinement refers to high precision and meets the needs of current lean production. The main movement uses linear guide rails to avoid stress on the guide system. It can interface with most advanced automatic logistics system and build unmanned workshops, including AGV and EMS systems, and data interfaces, etc.

Jian means simple. The structure is simple and reliability is greatly improved. The new product “slimming” succeeded and became “A4 waist” of curing press, with room for 8 sets out of 7 sets.

Jie refers to saving. It saves energy consumption of the enterprise, saves floor area (no pit+ slimming), saves investment in infrastructure projects, and realizes fast installation, which can be completed in only two days.

Yue, refers to simple. The auxiliary working time is reduced, the production efficiency and the productivity utilization rate are improved, and 2600 more can be produced each year compared with curing press with the highest efficiency at present. Suitable for a wide range of bead sizes, can replace existing 45 ~ 52 inch mechanical curing press

Yao Mingxiao, deputy general manager, said that Arp Technology, as a professional curing press manufacturer, has worked hard in this field for more than 20 years and gained a lot of praise. Competition makes us progress. Arp Science and Technology will continue to adhere to principle of quality first, customer first, and do not forget your initiative mind to continuously innovate and bring more products and services with high added value to customers.

At demonstration site of new products, representatives of tire enterprises have asked enterprise research and development personnel to know more about excellent performance of products.